05/08/2024 6:50 p.m.

https://cablematic.com/en/products/thickness-gauge-pce-ct-25fn-PC272/

https://cablematic.com/en/products/thickness-gauge-pce-ct-25fn-PC272/

Thickness gauge PCE-CT 25FN

REF: PC272

Specifications

- Layer thickness gauge to quickly and accurately measure the thickness of the coating on metals.

- It is not necessary to indicate if the base is a ferrous or non-ferrous metal, the equipment recognizes it automatically.

- Small, compact design for one-handed use.

- It measures in a range up to 1500 µm with an accuracy of ±(3% + 1 µm).

- Screen to display the values in µm, mm and mils.

PVP

€138.90

Price including VAT:

€138.90

PVD

€129.32

PVP: Retail price.

Check conditions.

PVP: Sale price to distributors.

Check conditions.

Buy before:

Receive it:

7 business days

Delivery times are approximate. Cablematic is not responsible for delays.

warranty

returns

safe

Specifications

- Layer thickness gauge to quickly and accurately measure the thickness of the coating on metals.

- It is not necessary to indicate if the base is a ferrous or non-ferrous metal, the equipment recognizes it automatically.

- Small, compact design for one-handed use.

- It measures in a range up to 1500 µm with an accuracy of ±(3% + 1 µm).

- Screen to display the values in µm, mm and mils.

Keywords

Did not find what you were looking for? These topic could help you

More info

The coating thickness gauge is an easy-to-use, one-handed device that helps save time and cost when measuring coating thicknesses. It has a battery status indicator. This tool is useful for measuring the coating thickness on ferrous and non-ferrous metals. Manufactured by PCE with reference PCE-CT 25FN.

Specifications

Specifications

- Layer thickness gauge to quickly and accurately measure the thickness of the coating on metals.

- It is not necessary to indicate if the base is a ferrous or non-ferrous metal, the equipment recognizes it automatically.

- Small, compact design for one-handed use.

- It measures in a range up to 1500 µm with an accuracy of ±(3% + 1 µm).

- Screen to display the values in µm, mm and mils.

- Indication of MIN/MAX and MEAN values.

- Battery status indication.

- Different units.

- Automatic disconnection.

- Gross Weight: 300 g

- Number of packages: 1

- Master-pack: 1

Technical terms

- Battery charging cycles

Battery charging cycles

When calculating the life of a battery it will be necessary to know the number of charge cycles that can be performed until the battery does not begin to lose its capacity.

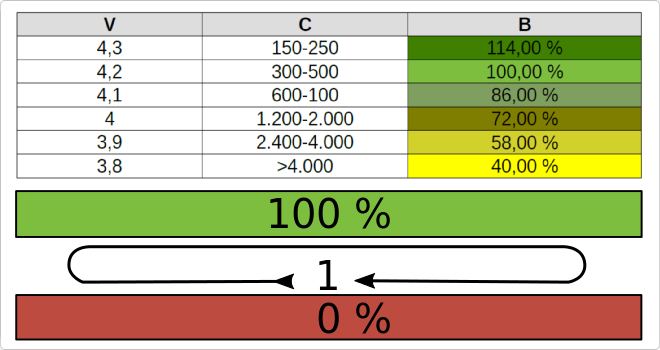

Depending on the type of battery these charging cycles can vary, the most common being the mobile batteries, manufactured Li-Ion or Li-Po, which have a duration of between 300 and 500 charging cycles according to model and manufacturer.

Once thisE limit we will notice how the battery loses duration of operation, arriving to lose up to 25% of its capacity of load.

At this point it will be necessary to evaluate a battery change.

It should be noted that usage and charging habits can significantly affect battery life. For example, factors such as heat, charge the battery several times a day without it is almost exhausted, etc. Will be affectedits duration.

Therefore, to get the most out of the battery we must know when a full charge cycle is performed, and try to avoid misuse of charge, to increase its useful life.

A charging cycle is considered when the battery has been discharged or its 100% charge has been used.

The manufacturers advise that the charge is never made below the 58% battery, since the battery voltage would not fall so lowTo, so you could end up winning up to 4000 charge cycles.

Tips to increase the life of a battery.

Depending on the type of battery these charging cycles can vary, the most common being the mobile batteries, manufactured Li-Ion or Li-Po, which have a duration of between 300 and 500 charging cycles according to model and manufacturer.

Once thisE limit we will notice how the battery loses duration of operation, arriving to lose up to 25% of its capacity of load.

At this point it will be necessary to evaluate a battery change.

It should be noted that usage and charging habits can significantly affect battery life. For example, factors such as heat, charge the battery several times a day without it is almost exhausted, etc. Will be affectedits duration.

Therefore, to get the most out of the battery we must know when a full charge cycle is performed, and try to avoid misuse of charge, to increase its useful life.

A charging cycle is considered when the battery has been discharged or its 100% charge has been used.

The manufacturers advise that the charge is never made below the 58% battery, since the battery voltage would not fall so lowTo, so you could end up winning up to 4000 charge cycles.

Tips to increase the life of a battery.

- Avoid extreme heat or cold or very long applications of the device.

- Charge the battery as often as you can.

- Fully discharge the battery from time to time.

- Do not let the battery run out completely before charging.