01/23/2026 10:01 a.m.

https://cablematic.com/en/products/thickness-gauge-pce-ct-5000h-PC276/

https://cablematic.com/en/products/thickness-gauge-pce-ct-5000h-PC276/

Thickness gauge PCE-CT 5000H

REF: PC276

Specifications

- Instrument to quickly determine the coating thickness on ferrous and non-ferrous metals.

- Non-destructive measurement method.

- Operating principle: magnetic induction for ferrous metals and Eddy Current for non-ferrous metals.

- Internal memory.

- Automatic disconnection.

PVP

€310.88

Price including VAT:

€310.88

PVD

€289.45

PVP: Retail price.

Check conditions.

PVP: Sale price to distributors.

Check conditions.

5 business days

The delivery times are approximate and may vary depending on the selected carrier.

warranty

returns

safe

Specifications

- Instrument to quickly determine the coating thickness on ferrous and non-ferrous metals.

- Non-destructive measurement method.

- Operating principle: magnetic induction for ferrous metals and Eddy Current for non-ferrous metals.

- Internal memory.

- Automatic disconnection.

Keywords

Did not find what you were looking for? These topic could help you

More info

The thickness gauge also has an internal memory, which allows the measurement results to be stored. Thickness gauge calibration can be performed using 1 to 4 points and zero point calibration is also performed. This makes it possible to ensure the reliability of the measurement results. It also automatically turns off after a period of inactivity, helping to save energy. In conclusion, the use of a thickness gauge for non-destructive testing is a useful tool to guarantee a quality coating and avoid product waste. Manufactured by PCE with reference PCE-CT 5000H.

Specifications

- Instrument to quickly determine the coating thickness on ferrous and non-ferrous metals.

- Non-destructive measurement method.

- Operating principle: magnetic induction for ferrous metals and Eddy Current for non-ferrous metals.

- Internal memory.

- Automatic disconnection.

- Adjustment of limit values.

- 1 to 4 point calibration and zero point calibration.

- Ideal for checking the quality of the coating in the control of entry or exit of goods.

- Gross Weight: 560 g

- Number of packages: 1

Technical terms

- Induction charging

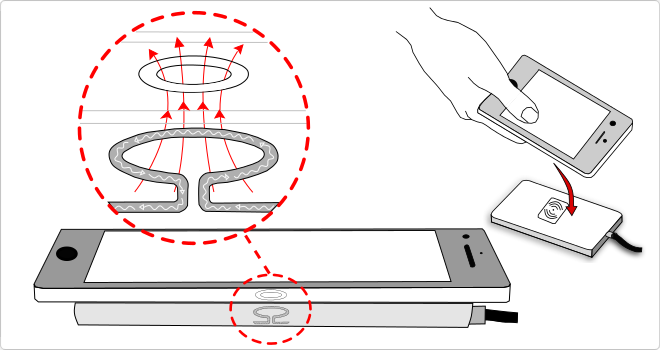

Induction charging

Induction charging is a process by which a device can be a charger without direct contact.

Electrification or charging by induction is carried out when a body with an electric charge approaches another with a neutral charge, which causes a redistribution of charges due to the repulsion between them or when the neutral charge is rearranged upon receiving a nearby body with electric charge.

This reorderingor redistribution causes some areas to be loaded positively or negatively, by loading the device.

We can mostly find this charging system in mobile phones or smart watches which can be charged without connecting them with cable, it is only necessary to leave them in the induction base and the charging procedure will be performed automatically.

It must be said that not all devicesthey are of this technology, but it is possible in many cases to adapt them.

Electrification or charging by induction is carried out when a body with an electric charge approaches another with a neutral charge, which causes a redistribution of charges due to the repulsion between them or when the neutral charge is rearranged upon receiving a nearby body with electric charge.

This reorderingor redistribution causes some areas to be loaded positively or negatively, by loading the device.

We can mostly find this charging system in mobile phones or smart watches which can be charged without connecting them with cable, it is only necessary to leave them in the induction base and the charging procedure will be performed automatically.

It must be said that not all devicesthey are of this technology, but it is possible in many cases to adapt them.